Moulds

Many colours and flavours

The number of variants in moulds and dies is too great to list here.

Whether it is a 1-part mould with simple geometry, or a complex multi-part mould with moving parts and complex geometry, our many years of experience allow us to design and produce any mould you need.

Below, we have distinguished the different groups with a few examples.

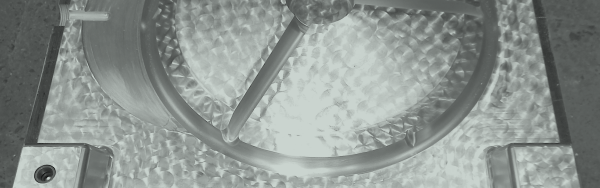

Injection or casting moulds for plastic and resin products

In these molds, the product is formed by injecting or casting the material in liquid form.

The phase from liquid form to final solid form depends on the raw materials used, for some materials the mould is cooled to speed up this process, for other materials it is quicker to heat up the mold.

Some examples:

- Injection molds

- Encapsulation molds

- RIM molds

- Spray molds

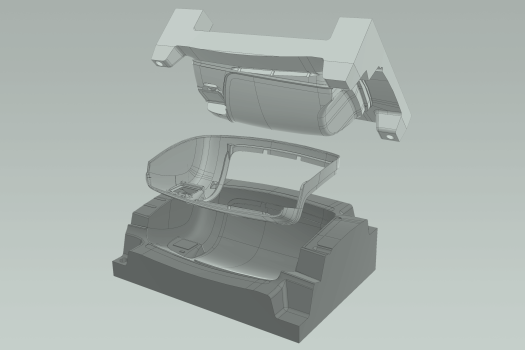

Moulds for composite products

- Hand/wet lay-up

- Vacuum baggin

- Resin infusion

- Prepreg autoclave and preform moulds

- Thermocompression

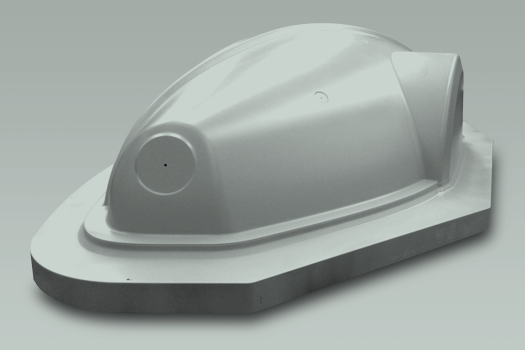

Moulds for thermoplastic products

- Vacuum molds

- Drapery molds

- Rotational molding

Moulds for forming non-plastics

- Concrete molds

- Scallops

- Plaster molds

- Paper molds

- Meat and chocolate molds

Other

- Press molds for rubber

- Hammer molds