Models

Infinite applications

Tailormold started as a model-making company for the foundry world. We still use the experience and knowledge we have built up over the years to produce models today. The model is the actual piece that is milled with the necessary provisions for the foundry process. This model is the basis on which the final moulds are made.

Casting models and core boxes

Casting models and core boxes are used by the foundry to make molds in sand in which the castings are produced.

The models are made of wood, PU or aluminium; the choice of material depends on size, abrasive properties and dimensional stability.

In certain cases, casting the models in synthetic resin may be more economical. This typically occurs with model plates on which several identical models are to be placed and when duplicating or repairing existing models.

Models for composite processing

Most composite processors make their own molds. For them, we make the models on which they can then make their moulds by lamination or spraying.

Direct mould (plug) versus model

Although there are often certain advantages of using a model to make a mould, for certain applications it is sufficient to produce a mould directly.

The extra step of laminating or spraying is then avoided, making the process more economical.

Elements to consider are quantities, surface quality and any need for seamless surfaces.

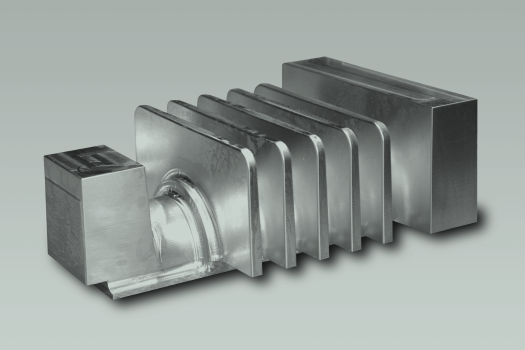

Gieterijmodel klaar voor montage op de modelplaat.

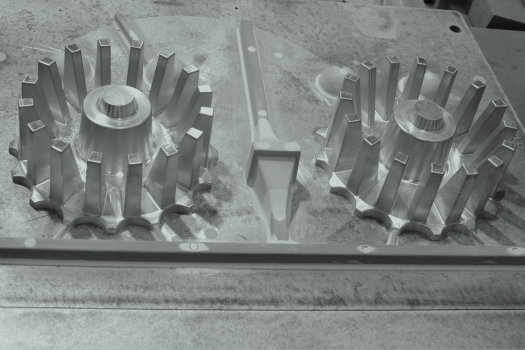

Modelplaat met modellen en aangietsysteem.

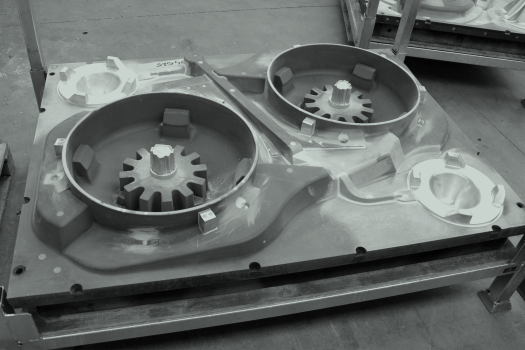

Aangepast gieterijmodel, combinatie van kunststof en aluminium.