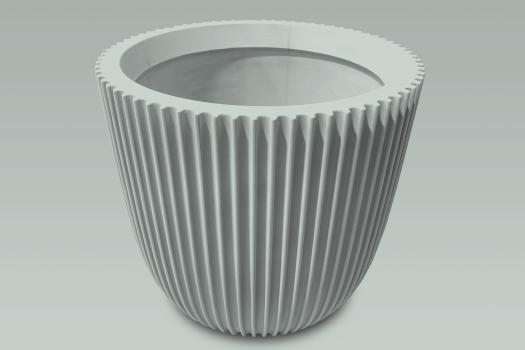

Prototypes

This statement is all the more true for new products. In order to ascertain the design, fit, mounting options and so forth, it is advisable to evaluate the product in a cheaper version before proceeding with the production of models or molds. That is why we make prototypes and visual models. If required, we even make a functional model so that it can be tested in real-life conditions. Often, prototypes are made to scale to increase their manageability.

No matter the desired prototype, we will assist you with our experience to achieve the most cost-efficient and functional solution.

Important considerations in the production of prototypes

Choice of material

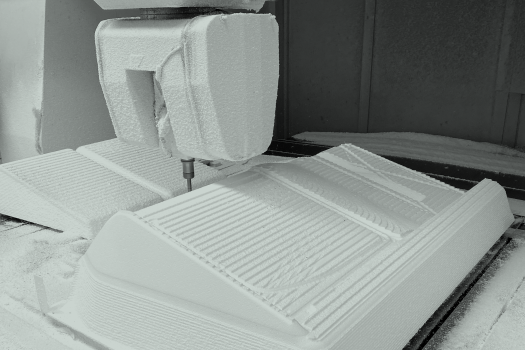

Often, for cost reasons, or for the production method, the prototype is made from a different material than the final product. If the prototype is only intended for visual inspection, this is not a problem, but if functional tests are also performed on the prototype, this must be taken into account.

Wall thickness and radii

A small wall thickness and small radii can cause problems for milling. It is then recommended to increase the wall thickness and radii. If this is not possible, it is advisable to produce the prototype via proto-molds.

Numbers

If several pieces are needed, for cost reasons it is better to opt for making a mould, in which the prototype is formed.

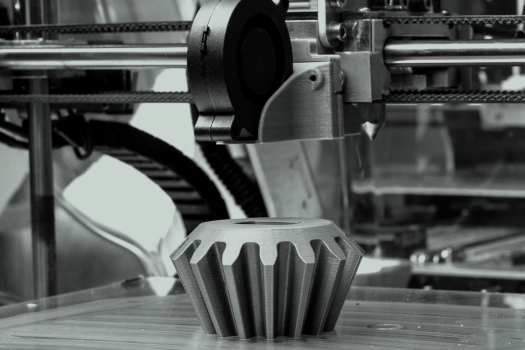

3D Printing

3D printing is usually more cost-effective than traditional techniques for prototyping complex products. For larger products, larger than the print bed, this is not always the case. Additional issues are the material properties that are often different and the fact that larger models consist of several, glued, pieces.

3D geprint model voor silicone afgiet.

Frezen van een prototype uit PUR.

3D printing